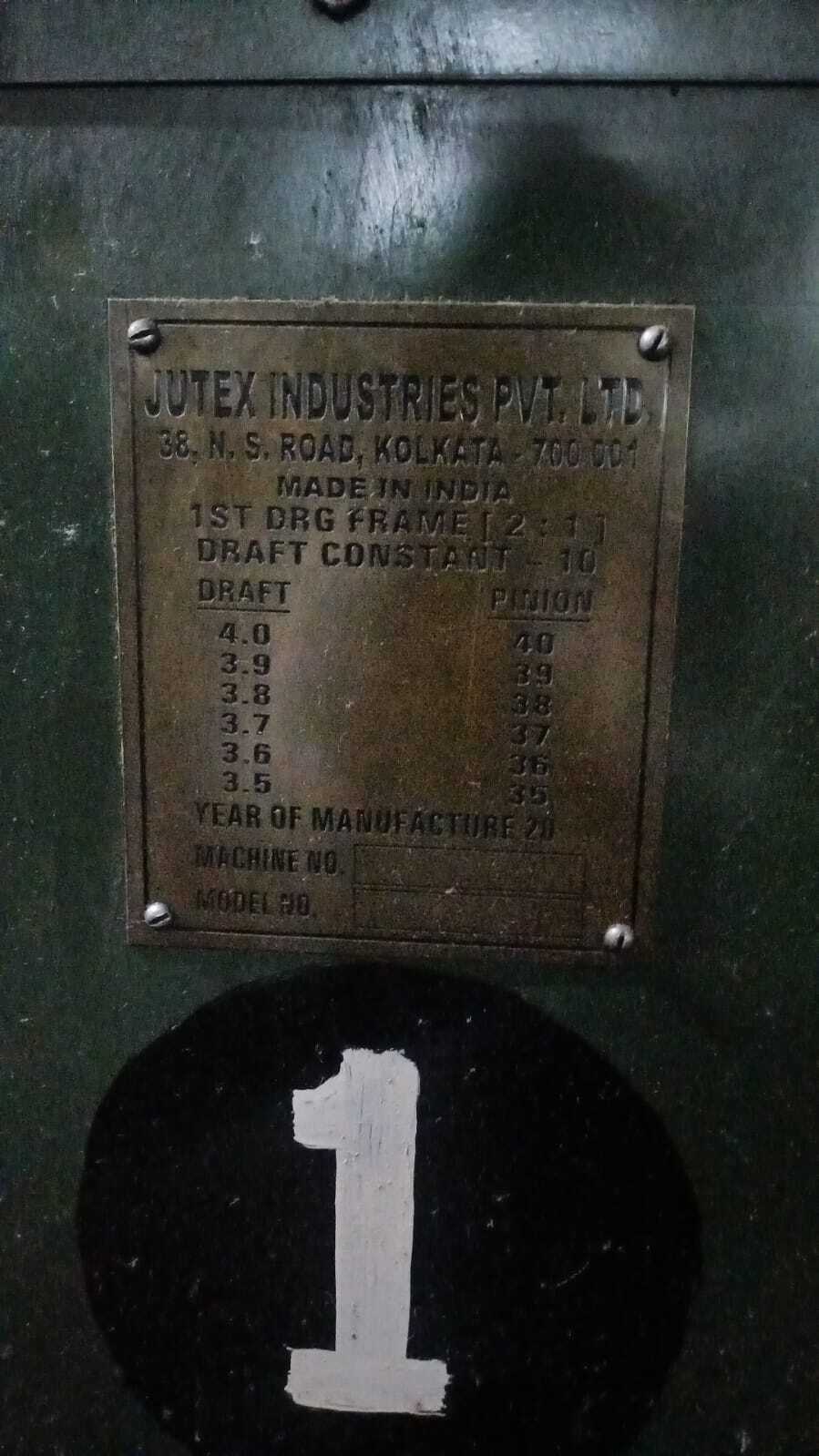

First Drawing Machine

Product Details:

- Product Type First Drawing Machine

- General Use Wire Drawing and Processing

- Material Mild Steel, Cast Iron

- Type Industrial Machine

- Weight (kg) Approx. 2500

- Computerized No

- Automatic Semi Automatic

- Click to View more

X

First Drawing Machine Price And Quantity

- 1 Unit

First Drawing Machine Product Specifications

- Blue and White

- Semi Automatic

- Manual

- Variable (Depending on Material)

- Manual or Mechanical

- Roller Type

- 415 V

- Wire Drawing and Processing

- First Drawing Machine

- No

- Mild Steel, Cast Iron

- Industrial Machine

- Drawing/Stretching

- Positive

- High Efficiency, Robust Design

- Panel Controlled

- Manual

- Approx. 2500

- Automatic

- 10 kW

- 3000 mm x 1200 mm x 1200 mm

First Drawing Machine Trade Information

- 10 Unit Per Month

- 1 Months

- Asia

Product Description

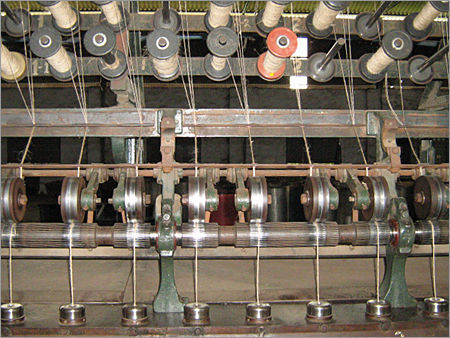

First Drawing Machine (7 Head 7 Delivery)

Screw Gill 1st Drg Machine having 7 heads 7 Deliveries (2 Sliver per head & 1 Delivery per head) 14 reach, Fitted with roll feed at back and can turning & packing motions with high-density packers, complete with electrical.

Engineered for Precision and Performance

Manufactured in India, the First Drawing Machine delivers precise wire drawing and processing for diverse industrial requirements. Its six-cone configuration and electronic dobby shedding offer accurate material handling, while the water-cooled drums and automatic grease lubrication minimize downtime and maximize efficiency. The robust gear and pulley transmission ensures dependable operation across variable material types and sizes.

User-Friendly Operation and Maintenance

With semi-automatic controls and a convenient panel interface, this machine supports easy setup and operation. Maintenance demands are significantly reduced thanks to the automatic lubrication system and durable mild steel/cast iron construction. Its noise output remains under 80 dB, promoting a safer, more comfortable work environment.

Flexible Application and Superior Surface Finish

Ideal for wire drawing and processing, the machines working range adjusts based on input material. Powder-coated surfaces guarantee lasting protection and a professional appearance, and advanced features like roller-type take-up and positive let-off further streamline the wire drawing process for manufacturers, exporters, and suppliers.

FAQs of First Drawing Machine:

Q: How does the First Drawing Machine improve the efficiency of wire processing operations?

A: The machine enhances efficiency through its six-drum setup, high drawing speed (up to 70 m/min), and robust gear-and-pulley transmission, enabling rapid reduction of wire diameters while maintaining consistent quality and minimizing downtime via automatic lubrication and water-cooled drums.Q: What materials are compatible with this wire drawing machine?

A: The machine is designed for versatility and is suitable for mild steel, as well as other compatible metals within the specified inlet (6 mm) and outlet (1 mm) diameter range. Its variable working range adapts according to the specific properties of the input material.Q: When should the water cooling and automatic lubrication systems be used?

A: Both the water-cooled drums and automatic grease lubrication operate continuously during the machines operation. They activate as needed to maintain ideal temperatures and smooth component movement, ensuring safe, uninterrupted performance and extended machine lifespan.Q: Where is this drawing machine typically used?

A: This machine is primarily used in industrial environments such as wire manufacturing plants, processing facilities, and factories involved in large-scale wire production, especially those requiring high efficiency, durability, and semi-automatic operation.Q: What is the process for adjusting the wire diameter and speed?

A: Operators can select the desired inlet and outlet wire diameters (between 6 mm and 1 mm) via the control panel, and adjust the drawing speed within the machines 70 m/min maximum limit. Fine-tuning ensures optimal output and material handling for each application.Q: How does the user benefit from features like electronic dobby shedding and automatic filling insertion?

A: Electronic dobby shedding automates intricate parts of the drawing process, increasing precision, while automatic filling insertion reduces manual intervention, lowering labor demands and potential for error, resulting in improved productivity and product consistency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email